What is the use of filter press in oil industry?

he Use of Filter Press in the Oil Industry

Introduction to Filter Press in Oil Industry

● Overview of Filter Press Technology

The filter press is an essential technology in the oil industry, offering robust solutions for separating solids from liquids. This highly efficient mechanism has revolutionized various stages of oil production, from extraction to refining. Leveraging mechanical pressure, the filter press effectively removes impurities, making it indispensable for maintaining the quality and purity of oil products.

● Importance in the Oil Industry

Filter presses are critical in the oil industry due to their ability to handle vast quantities of fluid, ensuring high levels of filtration efficiency. They significantly improve product quality, reduce waste, and enhance operational efficiency, making them a vital part of modern oil production processes.

Historical Development of Filter Press

● Evolution of Filter Press Technology

The technology behind filter presses dates back centuries, with initial designs being relatively simple and manually operated. Over time, technological advancements have led to the development of more sophisticated and automated filter presses. These advancements have made the technology more reliable, efficient, and suitable for the demanding needs of the oil industry.

● Milestones in Its Adoption in the Oil Industry

The widespread adoption of filter presses in the oil industry can be traced back to the early 20th century. Key milestones include the introduction of automated controls, improvements in filter media, and the development of high-capacity models. Today, oil filter press manufacturers continue to innovate, enhancing the technology to meet the ever-evolving requirements of the industry.

Basic Working Principle of Filter Press

● Mechanism of Filtration Process

At its core, a filter press functions by applying pressure to a slurry, separating solids and liquids through a series of filter plates and cloths. The slurry is pumped into the press, and as pressure builds, the liquid is forced through the filter media, leaving the solids behind. This results in a cake of filtered solids, which can then be easily removed.

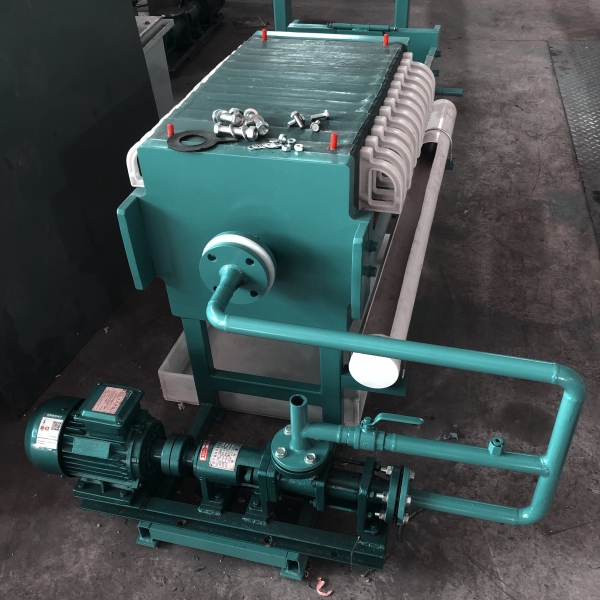

● Key Components of a Filter Press

A typical filter press consists of several key components, including the filter plates, filter cloths, a hydraulic system, and a feed pump. Each component plays a crucial role in ensuring efficient and effective filtration. The plates support the filter cloths and create the chambers where filtration occurs, while the hydraulic system provides the necessary pressure.

Primary Applications in Oil Extraction

● Use in Crude Oil Extraction

In the early stages of oil extraction, crude oil is often mixed with a variety of impurities, including water, solids, and other contaminants. Filter presses are used to remove these impurities, ensuring that the crude oil is of a higher quality before it undergoes further refining processes. This initial filtration step is crucial for maintaining the efficiency of downstream operations.

● Role in Refining Processes

During the refining process, filter presses are used to remove finer impurities and by-products that result from chemical reactions. They help in producing a purer end product, which is essential for meeting industry standards and consumer expectations. By incorporating filter presses into refining operations, oil filter press suppliers can ensure consistent quality and performance of their products.

Benefits of Using Filter Press

● Efficiency and Cost-Effectiveness

One of the primary benefits of using filter presses in the oil industry is their efficiency. They can process large volumes of fluid quickly, reducing downtime and increasing throughput. Additionally, filter presses are cost-effective, as they reduce the need for chemical treatments and other costly filtration methods. This makes them an attractive option for oil filter press factories looking to optimize their operations.

● Environmental Benefits

Filter presses also offer significant environmental benefits. By effectively removing contaminants, they reduce the amount of waste generated during oil production. This not only minimizes the environmental impact but also helps companies comply with stringent environmental regulations. Furthermore, the use of filter presses can lead to better resource management, as filtered solids can often be repurposed or disposed of more sustainably.

Types of Filter Press Used in Oil Industry

● Plate and Frame Filter Presses

Plate and frame filter presses are among the most commonly used types in the oil industry. They consist of alternating plates and frames, which create a series of chambers where filtration occurs. This design allows for easy cleaning and maintenance, making them a popular choice for many oil filter press manufacturers.

● Automatic vs. Manual Filter Presses

While manual filter presses require human intervention to operate, automatic filter presses offer greater convenience and efficiency. Automatic systems can handle larger volumes and operate continuously, reducing labor costs and increasing productivity. However, manual filter presses are still widely used in smaller operations or where budget constraints exist.

Maintenance and Operational Best Practices

● Routine Maintenance Tasks

To ensure the longevity and efficiency of a filter press, regular maintenance is essential. Key tasks include inspecting and cleaning the filter plates, checking the hydraulic system for leaks, and ensuring the feed pump is in good working condition. Regular maintenance helps prevent costly breakdowns and extends the lifespan of the equipment.

● Tips for Optimal Performance

For optimal performance, it is crucial to use the correct filter media and maintain proper operating conditions. This includes monitoring the pressure levels, ensuring the slurry feed is consistent, and avoiding overloading the press. By following these best practices, oil filter press suppliers can ensure that their equipment operates at peak efficiency.

Challenges and Solutions

● Common Operational Issues

Despite their many advantages, filter presses can encounter operational challenges. Common issues include clogging of the filter media, uneven pressure distribution, and mechanical failures. These problems can lead to reduced efficiency and increased downtime.

● Innovations Addressing These Challenges

To address these challenges, oil filter press manufacturers have developed several innovations. These include advanced filter media designed to resist clogging, automated pressure control systems, and more robust hydraulic components. These innovations help improve the reliability and performance of filter presses, making them more effective in demanding oil industry applications.

Case Studies and Real-World Applications

● Successful Implementations

Numerous case studies demonstrate the successful implementation of filter presses in the oil industry. For example, one major oil filter press supplier implemented an automated filter press system in a large refinery, resulting in a 30% increase in throughput and a significant reduction in operating costs. Such success stories highlight the tangible benefits of using filter presses.

● Lessons Learned from Industry Examples

From these case studies, several key lessons emerge. First, proper maintenance and operation are crucial for maximizing the efficiency of a filter press. Second, selecting the right type of filter press for the specific application can make a significant difference in performance. Lastly, continuous innovation and adaptation are essential for staying competitive in the oil industry.

Future Trends and Innovations

● Technological Advancements

The future of filter press technology in the oil industry looks promising, with several exciting advancements on the horizon. Innovations such as smart sensors, automated control systems, and advanced filter media are set to further enhance the efficiency and reliability of filter presses. These advancements will enable oil filter press factories to meet the increasing demands of the industry.

● Predicted Future Developments in Filter Press Applications

Looking ahead, we can expect to see filter presses playing an even more critical role in the oil industry. As regulations become stricter and the demand for high-quality oil products increases, the need for efficient filtration solutions will grow. Oil filter press manufacturers and suppliers will continue to innovate, developing new technologies and solutions to meet these evolving needs.

Conclusion

In conclusion, the filter press is an indispensable tool in the oil industry, offering numerous benefits ranging from improved efficiency and cost-effectiveness to significant environmental advantages. With a rich history of technological development and a promising future of continued innovation, filter presses will remain a vital component of oil production processes. By understanding their working principles, applications, and best practices for operation and maintenance, industry professionals can leverage this technology to optimize their operations and achieve greater success.

● About HZFILTER

HZFILTER is a leading manufacturer of high-quality filter presses, specializing in solutions for the oil industry. With a commitment to innovation and excellence, HZFILTER offers a wide range of products designed to meet the specific needs of oil extraction and refining processes. Whether you are looking for a wholesale oil filter press or tailored solutions for your operations, HZFILTER provides reliable and efficient equipment to help you achieve your goals.

评论

发表评论